| Items |

1314

Camseal® 1/2 to 1-1/2 Inch (in) Pipe Size 5E Size Metal-Seated Cartridge-Style Top Entry Zero Leakage Ball Valve

|

1315

Camseal® 1/2 to 1-1/4 Inch (in) Pipe Size 7E Size Metal-Seated Cartridge-Style Top Entry Zero Leakage Ball Valve

|

1316

Camseal® 1/2 to 1-1/2 Inch (in) Pipe Size 5F Size Metal-Seated Cartridge-Style Top Entry Zero Leakage Ball Valve

|

1317

Camseal® 2 to 2-1/2 Inch (in) Pipe Size 7H Size Metal-Seated Cartridge-Style Top Entry Zero Leakage Ball Valve

|

1318

Camseal® 1-1/2 to 4 Inch (in) Pipe Size 9H Size Metal-Seated Cartridge-Style Top Entry Zero Leakage Ball Valve

|

|

Description

|

N/A

Camseal® Metal-Seated, Cartridge-Style, Top Entry, Zero Leakage Ball Valves save significant time and money on installation, maintenance, replacement and downtime.

|

|

Brands

|

N/A

Camseal® Conval

|

|

Pipe Size

|

N/A

1/2 to 1-1/2 inDN15 to DN40

|

N/A

1/2 to 1-1/4 inDN15 to DN32

|

N/A

1/2 to 1-1/2 inDN15 to DN40

|

N/A

2 to 2-1/2 inDN50 to DN65

|

N/A

1-1/2 to 4 inDN40 to DN100

|

|

Size Code

|

N/A

5E

|

N/A

7E

|

N/A

5F

|

N/A

7H

|

N/A

9H

|

|

American Society of Mechanical Engineers (ASME) Class Pressure Rating

|

N/A

1700 3100

|

N/A

4500

|

N/A

2700

|

N/A

1700 3100

|

N/A

4500

|

|

A

|

N/A

7 1/4 in184 mm

|

N/A

9 1/4 in235 mm

|

N/A

7 1/4 in184 mm

|

N/A

9 1/4 in235 mm

|

N/A

11 in279 mm

|

|

B

|

N/A

1 5/8 in42 mm

|

N/A

2 in51 mm

|

N/A

1 5/8 in42 mm

|

N/A

2 in51 mm

|

N/A

2 11/32 in60 mm

|

|

D

|

N/A

3 1/4 in83 mm

|

N/A

4 in102 mm

|

N/A

3 1/4 in83 mm

|

N/A

4 in102 mm

|

N/A

4 11/16 in119 mm

|

|

F

|

N/A

5/8 in16 mm

|

N/A

5/8 in16 mm

|

N/A

3/4 in19 mm

|

N/A

1 1/16 in27 mm

|

N/A

1 1/16 in27 mm

|

|

G

|

N/A

7 3/8 in187 mm

|

N/A

10 5/32 in258 mm

|

N/A

10 5/16 in262 mm

|

N/A

10 5/32 in258 mm

|

N/A

11 1/2 in292 mm

|

|

J

|

N/A

15 3/16 in386 mm

|

N/A

24 3/16 in614 mm

|

N/A

24 3/16 in614 mm

|

N/A

31 5/8 in803 mm

|

N/A

32 in813 mm

|

|

Standard Materials

|

N/A

SA-105 Carbon Steel SA-182-F22 CI.3 Alloy SA-182-F316 Stainless Steel SA-182-F316L Stainless Steel SA-182-F91 Alloy

|

|

Weight

|

N/A

30 1/4 lb13.7 kg

|

N/A

62 lb28.1 kg

|

N/A

30 lb13.6 kg

|

N/A

62 lb28.1 kg

|

N/A

100 lb45.4 kg

|

|

Industry Standards

|

N/A

Canadian Registration Numbers for all provinces Conformitè Europëenne (CE) International Organization for Standardization (ISO) 9001

|

|

Conval Camseal Ball Valve Provides Zero Leakage

|

N/A

Zero Body Leakage: The body/bonnet bolting for the top entry design is not susceptible to pipeline stresses - precluding the potential for leakage.

Zero Seat Leakage: Conval's Camseal has been type-tested using high pressure Nitrogen gas, achieving zero bubbles in four minutes. The result is industry leading performance with every valve and the longest in-service life compared to competitive brands.

Zero Stem Seal Leakage: Conval's exclusive Integral Gland Wrench concentrically loads the stem packing without tools, eliminating stem leaks and extending packing life. Live loading is available as an option.

|

|

Cartridge-Style Top Entry

|

N/A

With top entry access, maintenance and replacement of the cartridge internals are very convenient, with no effect on existing piping and welds.

|

|

Robust Stem-Ball Engagement

|

N/A

Reliable, accurate ball alignment is achieved due to the robust engagement between the one-piece stem and the ball.

|

|

Superior Bearing Support

|

N/A

Superior bearing support of the blowout-proof stem ensures proper axial alignment and Zero Seat Leakage even on actuated valves.

|

|

Stem-Ball Alignment

|

N/A

The easy to read Position Indicator Disc (patent pending) increases the visibility and accuracy of stem and ball alignment into the valve seat. This is especially important when adding an actuator to a valve or resetting valve actuation. It is also critical in severe applications such as steam where positive, sustainable shutoff is critical and even slight misalignments will compromise the ball/seat sealing band. This indicator eliminates the need for costly and multiple manufacturing features that have traditionally been used with less accuracy.

The indicator is self-securing to the stem; no set screws are required.

|

|

In-Line Servicing

|

N/A

In-line renewability can be accomplished in 30 minutes and restores Zero Leakage performance.

|

|

Integral Mounting Pad

|

N/A

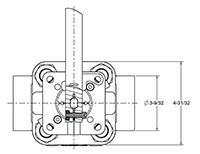

An ISO-5211 integral mounting pad facilitates error-free, air, motor and gear operator actuation due to superior rigidity, precise alignment and a fully-guided stem bearing system. Lockout capability is standard.

|

|

Two-Year Warranty

|

N/A

Conval is committed to unsurpassed quality. We are so confident of the quality of our product, that we offer a two-year warranty.

|

|

Standard Accessories

|

N/A

ISO-5211 Integral Mounting Pad Actuators - Electric, Pneumatic or Hydraulic, Gear Operator

|

|

Note

|

N/A

SW, BW, FNPT and a variety of ends TDP-1-2013 compliant and full port valves available.

Camseal® is a registered trademark of Conval, Inc.

United States Patent No. 7,267,323

|